|

How Are Repairs Done?

Teaching the staff how repairs and custom work is performed

One of the key ingredients in teaching the staff to sell repairs, custom design and watch repairs is know how it's done so they can sell it with ease to the customer and have a higher closing ratio.

Below are links that I found on YouTube where jewelers themselves have video recorded how something is done. Watching these will train the staff even better.

These were compiled in January 2016 and the link's worked at that time. If you find a link is "dead", please email me and I'll replace it.

Here is a sales example from David Geller on how to sell a sizing job, that’s white gold (we charge an extra $35 to rhodium plate), and also to check & tighten 5-20 stones in a ring. So to make a white gold engagement ring smaller with 7 stones (one in center and 3 on each side is $105 total.

=============================================================================

=============================================================================

"Mrs. Jones I know you probably think ring sizing is a simple job and shouldn’t be as much. It is one of the first things a jeweler is taught. But you don’t want a bad ring sizing. That’s when you can see where the ring was sized. A thinner shank or a line where it was sized. Our jewelers are trained no to do that, you won’t be able to see where it was sized.

In addition our jeweler will check and tighten all 7 stones and make sure they are secure. If they become loose in a year we’ll tighten them at no charge and if any fall out we’ll replace them at no charge.

Then our jeweler will polish your ring up so it looks the way your husband first gave it to you; it’ll shine like the top of the Chrysler building.

Lastly we can’t hire 75% of the jewelers applying for a job here; they aren’t up to our standards. In fact Marvin who will size your ring has been doing this for over 15 years and has worked here well over 10 years and you do want that kind of expertise, don’t you?”

===========================================================================

Did I fib or make anything up? Nope. Just explained how things are done and facts about our jeweler.

You can always shorten what I just typed to meet your style but this is the idea.

Below are links to YouTube videos on how work is done and I have typed above it my own explanation for the staff.

=======================================================================================

=======================================================================================

|

|

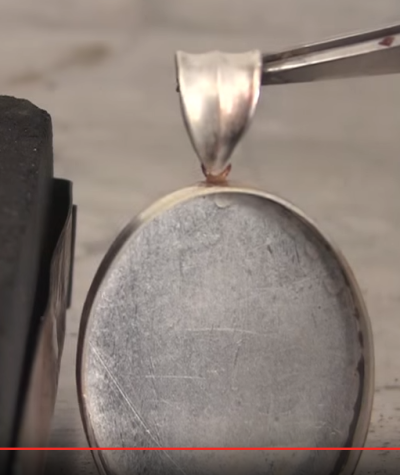

Example of a jeweler soldering

There are hundreds of ways to repair and make jewelry, most are accomplished with a torch. This video is to just give you an idea of what a jeweler does and the heat that is used when using a torch to repair or make jewelry

As you can see this bezel pendant has turned color from the heat and will have to be completely refinished at the end.

If the store used a laser welder this would minimize the polishing required and you wouldn't have to remove any stones.

But this is just to give you a slight insight into using a torch.

===========================================================================

|

|

|

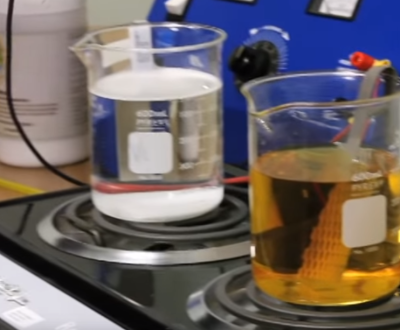

Check & tighten stones, refinish and rhodium plate

When a customer ask for her rings to be

- Cleaned

- Checks

- Polished

- Rhodium Plated

These all sound individually one at a time. These are actually 4 or more steps done to achieve one end. That end is to have all of the stones checked for tightness, tighten any loose stones, refinish the ring, remove any scratches, polish like new, make the ring "surgically" clean and then a 3 step rhodium playing process. It's more than just "dipping"

There are two videos.

The first one is from a store showing quickly the completed process.

The second video way below is from Stuller showing just the rhodium plating process itself. As you watch look at all of the solutions and equipment the store must buy and maintain just to give the customer back a "beautiful ring".

First Video-Complete Process:

Second Video-From Stuller-The Rhodium Plating Process

=========================================================================

|

|

|

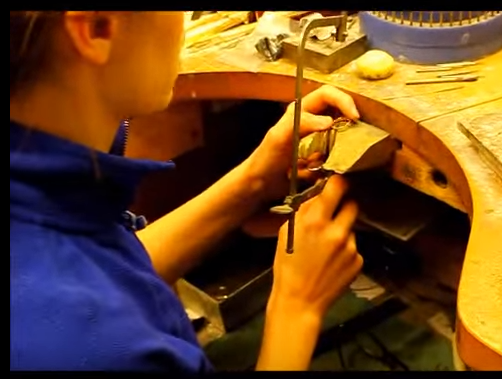

How to size a ring larger with a torch

This video shows how to size a ring larger, which is adding a piece into the bottom of the ring. Making a ring smaller is the same procedure except you remove a section and bring the ring together. This is being done with a torch.

============================================================================

|

|

|

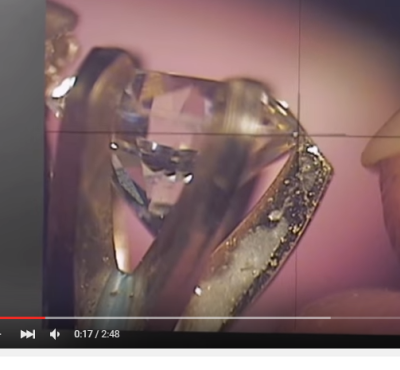

Sizing a ring using a laser

In the first sizing video the jeweler is using a torch to melt the solder and join the 2 sides of the shank together. The torch can get up to 1600 degrees. If you look at the ring as a clock sizing is done down at 6:00 while most stones are at 12:00 at the top. Fragile stones are far enough away from the heat of the torch that the sizing can be done quickly enough or use some heat protection to not harm fragile stones.

The only stones that can withstand this high heat are the colors of the American flag:

- Red: Faceted ruby (no to cabachons)

- Blue: Faceted blue sapphire (no again to cabachons)

- White: Diamonds (fractured filled diamonds can't take this heat, the filling will discolor)

Some rings have fragile stones down the side of the ring like channel set emeralds on the shank. or maybe the center stone is too valuable to take the risk of heat. Rather than removing and resetting the stones a laser welder is the answer!

A laser welder (cost near $20,000 or more!) does not use heat. Think of Star Trek and Captain James T Kirk using a laser gun. A beam of light is what joins the metal without any heat.

This picture is the view inside of the laser machine itself. This is what the jeweler sees. Although this is a prong repair picture I wanted to show yoiy the cross hairs for aiming, similiar to using a snipers rifle. The jewelers aims the laser and it hits the two pieces of metal and joins them together. Works similiar to how a broken bone joins itself back to the other broken bone and "joins as one". No heat.

Using a laser can save the customer the expense of removing and resetting stones and can save our store from the financial risk of damage to stones. The machine is expense and the jeweler requires extensive training. Because of this using a laser machine usually costs more but is well worth it.

===========================================================================

|

|

|

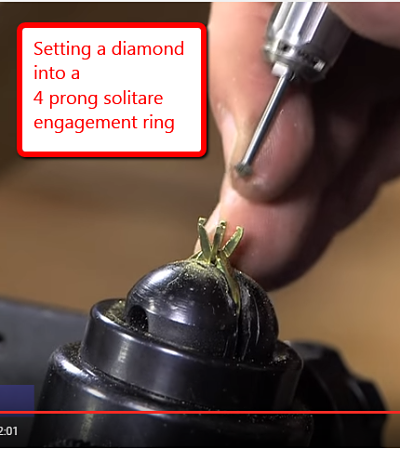

How to set a diamond into a solitare

In this video a Blaine Lewis shows how to set a diamond into an engagement ring. An excellent example how most prong settings are done

=========================================================================

|

|

|

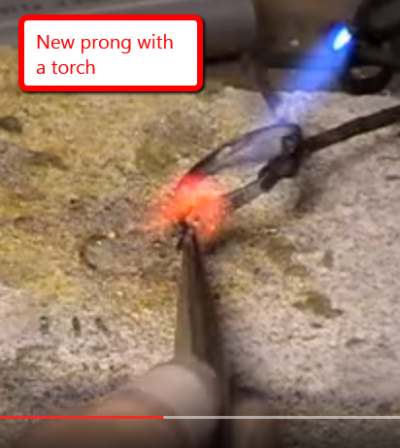

Rebuilding a prong using a torch

Here a jeweler is adding a gold wire to replace a broekn prong using a torch. The center stone has been removed, the gold prong will be replaced using a torch. Notice the amount of heat.

The only stones that can withstand this high heat are the colors of the American flag:

- Red: Faceted ruby (no to cabachons)

- Blue: Faceted blue sapphire (no again to cabachons)

- White: Diamonds (fractured filled diamonds can't take this heat, the filling will discolor)

===========================================================================

|

|

|

Rebuilding a prong using a laser

This demonstrates how to replace a broken prong on a diamond with a laser machine. This is to show you "procedure", most importantly there is no heat used. A diamond can take the heat of a torch doing this repair but other fragile stones cannot. Retipping an emerald with a torch always requires removal of the stone, then fixing the prong and resetting.

With a laser welder the stone doesn't have to be removed. No heat means virtually no chance of harming the stone

============================================================================

|

|

|

Setting a stone with sharp points

In this video Stuller shows us how to set a stone with sharp points. It happens to be a marquis shaped stone but the setting technique is the same for pear shape and princess cuts as well.

============================================================================

|

|

|

Setting a princess cut diamond

Showing how to set a 4 prong sharp point princess cut diamond. Doesn't show the ring polished but an excellent example of the skill and care that must go into this job.

=============================================================================

|

|

|

Bezel setting an emerald

This skilled setter is setting an emerald into a half bezel. This is not a ring, may be a pendant and he has sunken the pendant t into a water soluble "clay like" substance to hold the bezel in place. After the setting is completed the blue stuff will be removed, then pendant polished.

There is no audio description but the setter is carving away a seat for the stone to rest in. Then with a hammer attachment the bezel is carefully pushed over the stone.

Then the bezel is shaped, smoothed and at the end a graver is used to give sharp bright edges.

============================================================================

|

|

|

Pavè Setting

Pavè setting requires a certain skill and takes time to the job properly.

There are two different methods in doing pavè setting. The first one is hundreds of years old and this video shows how it's done. The jeweler would layout on the metal where the diamonds would sit, mark the metal, drill ones and then make the wholes larger to hold the diamonds. Walls are cut away, sloping down to where the diamond will sit, the beads are one by one raised by the jeweler with a sharp tool. Then rounded to form a bead, cleaned up further. Then polished.

Today some Cad/Cam programs can lout out the holes and drill them in the wax and make small beads that are there when it's cast. Then the jeweler makes the seats for the diamonds to sit and pushes the metal over. Although faster it will look "just fine" but not as detailed and nice as by hand.

This video is pavè setting done from scratch.

Click on the picture to see the video. Further down this page I have included another link for another bead/pavè setting video that shows a closer look at the hand work required. Use this when selling your custom jobs. It takes great skill to do this setting properly and nicely

Click this line to see the other video as well.

=============================================================================

|

|

|

Hand Carving a wax ring for stones

Excellent video taking a block of wax and carving out a ring that holds a center stone in prongs and eventually bead set stones on the side.

The next video below this one shows how a jeweler takes the wax and transforms it into metal

===========================================================================

|

|

|

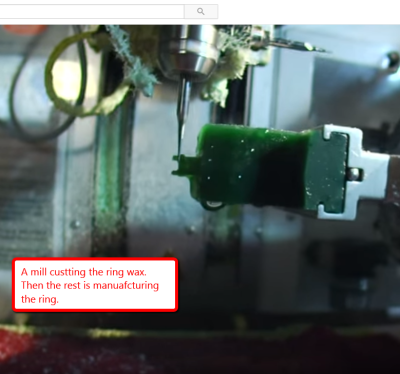

Casting a wax ring into metal

After a wax is made (either by hand or made from a mill from a cad/cam program) it still has to be made into metal.

The wax can be combined with other waxes to make many items at once. A wax rod (straw like) is added to the bottom of the ring, plugged into clay to stand tall. Then a steel cylinder (like a soup can) is secure around it. Then the cylinder is filled with water & a plaster type substance that hardens around it.

Placed into an oven the wax melts away, down through the wax rod (like a long exit hole) leaving an opening just like thru ring inside. Gold or other metal is melted and pour or thrown into the opening. Now there is a gold ring in it's place.

After removing the plaster like substance the rod (now gold as well-called a "sprue") is cut away and the ring is filed up and polished, ready to have stones et into the ring.

=============================================================================

|

|

|

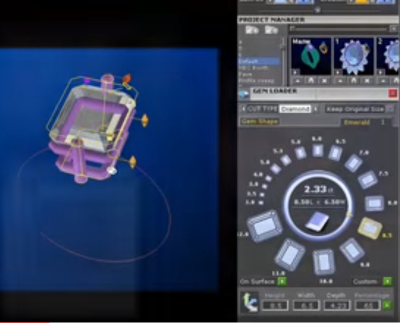

Design Jewelry on a computer-CAD/CAM

For thousands of years the lost wax process has been used to make jewelry, starting with a block of wax and a file.

Today's computer programs makes it easier to design and manufacture jewelry with better precision.

The software and any mills are expensive and easily takes over a year to master the software. More and more stores are adopting this technique.

Below are TWO videos on deigning jewelry with a computer aided design software.

This first one showcases Gemvision, one of the most widely used softwares in our industry and how it is used on a computer to make jewelry.

The second vide is from a store (Kessler's) who's video was made for it's customers. But it's so well done and in a short period of time shows the designing process through the computer process and then the mechanical mill cutting of the wax and then casting the ring into gold.

Then a jeweler melts the wax, pours the gold and makes the ring. Understanding these short videos will allow you to outshine the competition in your presentation to your customers of having your store do custom design. You don't have to understand how to use it, just understand in general how it's done.

Click on this picture below to see the Kessler video, very well done, short an sweet.

============================================================================

|

|

|

Stringing Pearls

This video shows the detail that goes into knotting a strand of pearls. Short and sweet.

|

|

|